3D-printed wood furniture could ship flat and self-assemble at home

The skill to significantly transform your condition is hailed in just the internet pages of comic textbooks and flicks as just one of the premier superpowers. The Hulk (now streaming on Peacock!) pulls it off as a result of a mixture of gamma radiation publicity — regardless of the truth that gamma radiation does not function that way — and uncontrolled anger.

Of class, nature has its own set of amazing transformations. All organisms change over time, either by the standard process of progress or through amazing and complicated metamorphoses, but some modify far more than many others. We frequently imagine of trees as stoic and primarily unchanging, at the very least about brief timescales. They stand resolute in our forests, swaying gently in the breeze, but their rigid bodies really do not present considerably in the way of changeover, correct? Not so speedy.

The morphology of wood is these kinds of that it harbors the ability to make drastic form modifications, specifically after it is lifeless. Anybody who has left a piece of untreated wooden exterior for way too very long has most likely noticed the way it warps after the moisture has evaporated. Typically, that’s negative information for everyone hoping to use that wood in a project, but the natural deformation qualities of wood are inspiring a new form of manufacturing.

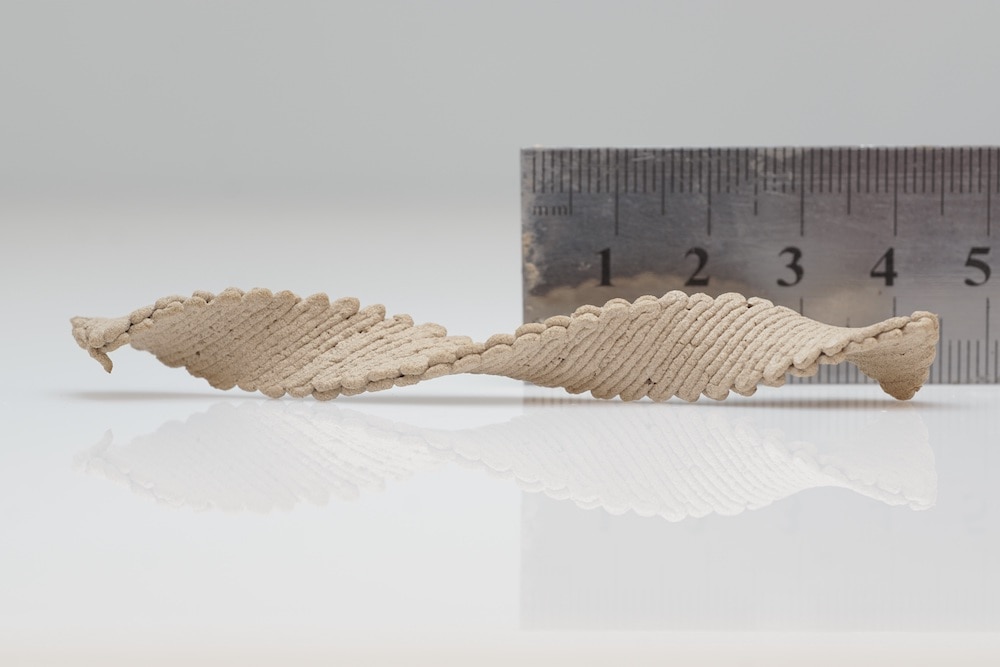

Doron Kam, a PhD college student at the Hebrew University of Jerusalem, and colleagues, have created a process for replicating the organic deformation of wooden in a additional managed placing using 3D printing. Their approach final results in sophisticated styles which include saddles and helices and could set the stage for the future of home furniture producing and transport. Their final results were presented at a latest meeting of the American Chemical Culture.

“When you chop down a tree water evaporates, but due to the fact of the way the cells are aligned, you have an uneven quantity lower. You get warping. We thought of carrying out the exact matter with 3D printing,” Kam told SYFY WIRE.

Researchers took wood waste particles, acknowledged as wood flour, and combined them with binders to generate a printable wood ink suitable for 3D printers. These types of an ink can be generated by slicing down trees and grinding them up, but it can also be generated from by now existing squander products and solutions like damaged home furniture or even the cotton fibers from outdated outfits. This product offers an option to plastics which are highly controllable and lengthy long lasting, but not approximately as sustainable.

In dwelling trees, the warping arrives from the loss of humidity as the wooden dries and the uneven way in which its fibers reduce moisture in excess of time. Scientists copy this course of action by way of humidity in the printing content. The moment a flat condition is laid down on the make plate it begins to get rid of moisture and the fibers within the wooden ink deform dependent on their orientation.

https://www.youtube.com/view?v=kVWXHlJlcPQ

“We’re utilizing extrusion-based mostly 3D printing which generally uses plastic filament and generates plastic squander. The idea is really very similar. We’re tuning the printing velocity, the circulation of the product, to make them additional or a lot less aligned and this results in diverse curvature when it dries,” Kam said.

By laying down lines of wood filament at various speeds next to a person yet another, or in layers on top rated of one particular one more, scientists can command the sorts of curvature the item achieves once it has dried. To day, they have built relatively simple styles as a proof of principle, but virtually any shape could be hypothetically reached with the proper combination of speeds, orientations, and levels.

“We don’t have complete regulate of the forces yet, but we have a seriously superior understanding of the mechanisms heading on. As we move forward, the field could go in quite a few directions,” Kam said.

How and when the printed object deforms into its permanent configuration is linked to the rate at which it loses dampness. That usually means that in the upcoming, it could be feasible to print furnishings at a production web-site, ship it as a flat package deal even though it however retains humidity, and then established it up at home. You could hypothetically established up your new flat chair in your residing area or kitchen area, go to get the job done, and arrive residence to a concluded item which assembled itself through the power of physics even though you had been absent.

Today, as soon as a condition has been achieved, it simply cannot be reversed, but that could possibly transform in the foreseeable future. Scientists are seeking at ways in which they may well be equipped to reintroduce humidity and reverse the method. If they can pull it off, it would definitely make packing and moving a complete large amount easier.

It really is a lover issue

Be part of SYFY Insider to get entry to exceptional films and interviews, breaking information, sweepstakes, and much more!

Signal Up for Cost-free